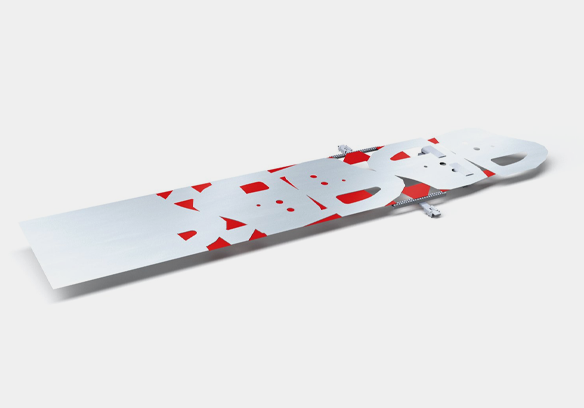

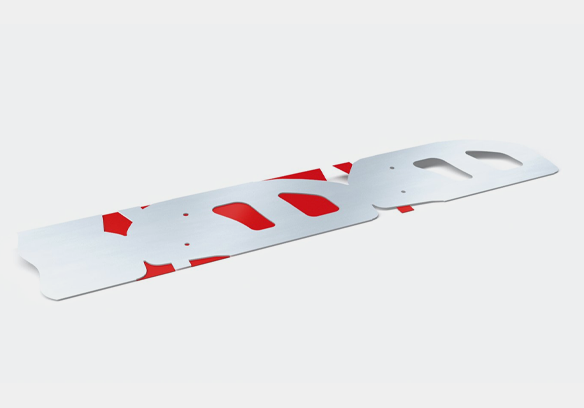

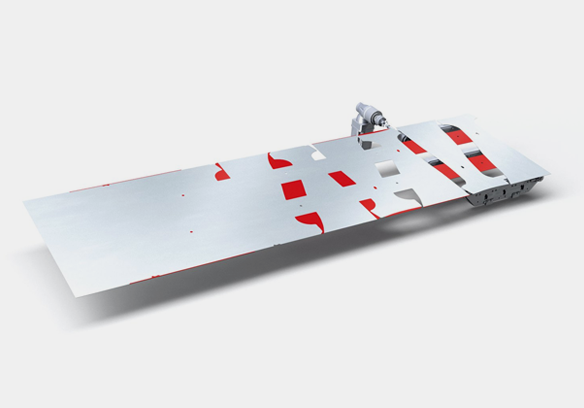

Blank cutting tools

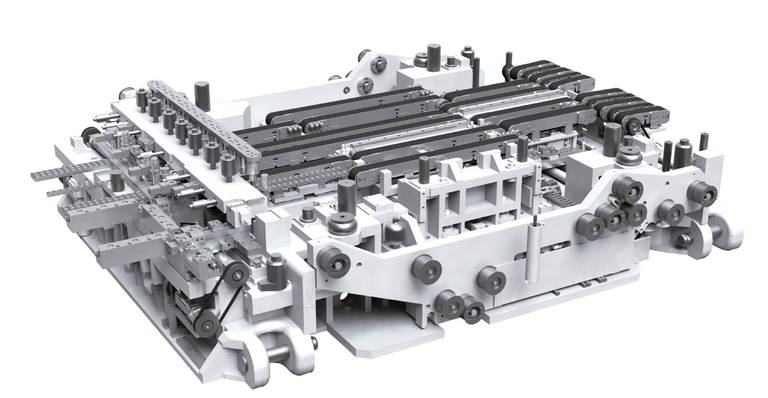

More than 30 years of experience, as well as around 1,200 manufactured blanking tools enable Schwarz to offer a wide range of these tools for different component complexities and output quantities.

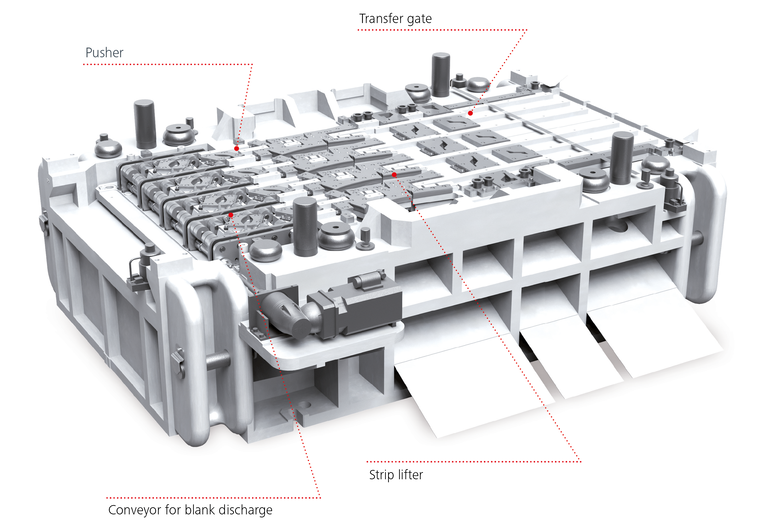

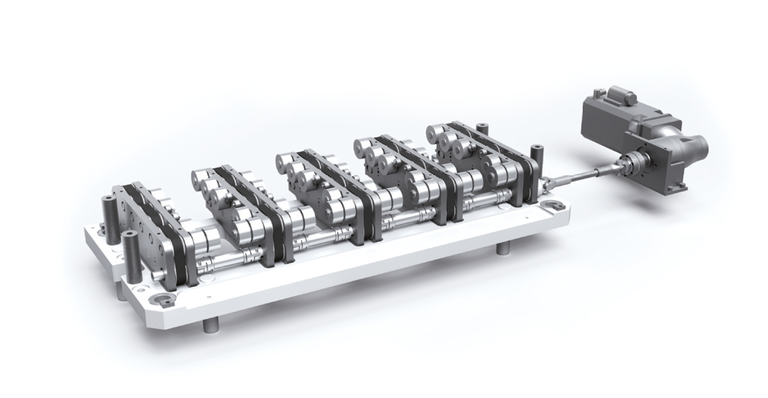

These can be up to 8-fold drop and thus enable a high productivity of the press. The optimisation of material utilisation through efficient strip plans is a key objective in the design of our blanking tools.

Here we can draw on the latest tool concepts and a wealth of experience in completed projects. Our optimised process approach of standardised design templates and consistent team production enables us to achieve very short delivery times. Our blanking tools also have a significantly shorter or no training period at the customer's site.

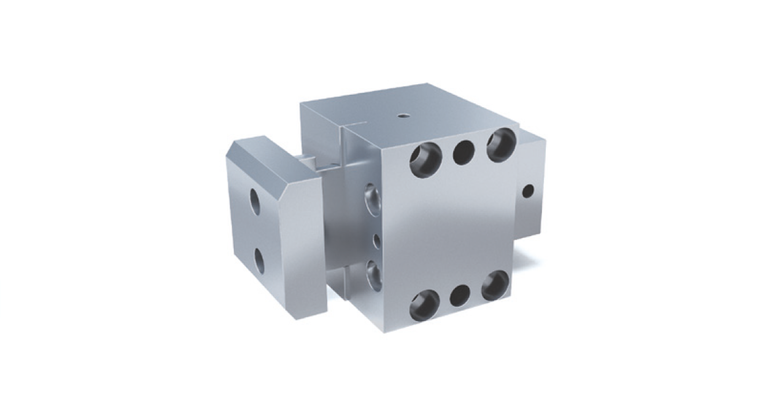

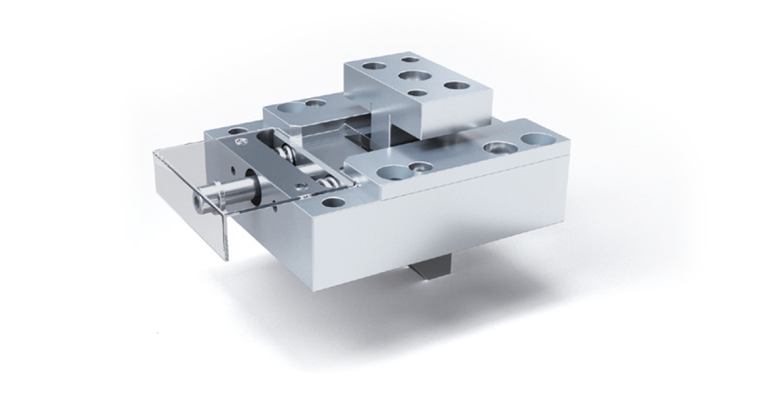

Our speciality is the production of universal cutting tools. Thanks to the production of different derivatives, several different blanks can be produced with one tool, even across projects. The adjustment to new blanks is of course highly automated. Thanks to the integration of mechatronic components, our tool designs ensure reduced investment costs and increased productivity.