Schwarz Werkzeugbau has been an established partner of the demanding automotive industry for 50 years and has developed from a small parts manufacturer to a full-service provider in forming and sheet metal forming.

Our self-conception is to take into account the strategic developments in the respective industry and to proactively offer new services based on the evolving requirements. Here, too, the focus is on increasing plant productivity and enabling new material concepts.

In recent years, we have used the experience successfully implemented in the automotive industry to gain a foothold in other sectors. The trends in the commercial vehicle industry are transport efficiency, comfort, safety and environmental friendliness. The resulting demands on vehicle construction are bringing the commercial vehicle industry closer to many aspects of the automotive industry.

This applies in particular to the surface quality of sheet metal parts and the aerodynamics of the vehicle system. We are extremely well positioned to accompany the coming developments with innovative tooling concepts.

The agricultural sector has developed into a high-tech industry in recent decades. In areas such as telematics, the technologies used even exceed the standards of the automotive industry. Cost pressure and the idea of sustainability are also having a strong impact on vehicle construction: Here, too, the specifications and conditions of increasing aerodynamics are causing a change in the processing of sheet metal parts.

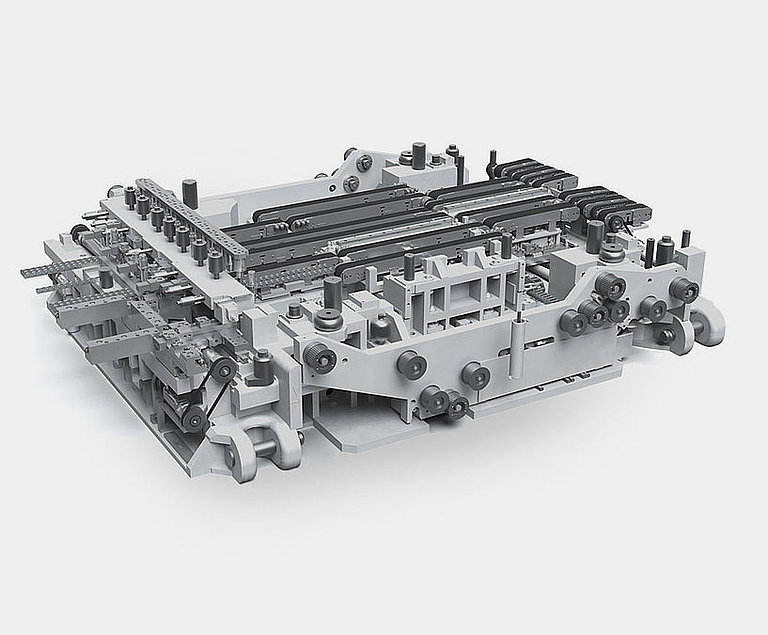

Schwarz Werkzeugbau has been an experienced partner in the design and manufacture of blanking tools for a wide range of applications in the metalworking industry for decades. Here our strengths lie in the integration of mechanical elements. By combining several work steps in one tool, not only the productivity but also the product quality is increased.

In addition to an integration of white goods into the increasing home automation, design aspects of the products play an increasingly important role. Here, too, cut and folded sheet metal parts are being replaced by formed parts. We have decades of experience with one of the market leaders in this industry.

With the Chassis chair from Wilkhahn, we have provided an example of how automotive expertise can be translated into new markets. The chair is manufactured from a single piece and in a single operation. The implementation of lightweight construction principles from the automotive industry has significant advantages in terms of productivity, costs, quality, durability and reproducibility. Many applications are conceivable in the furniture industry that can satisfy similar technical and economic criteria in this way.